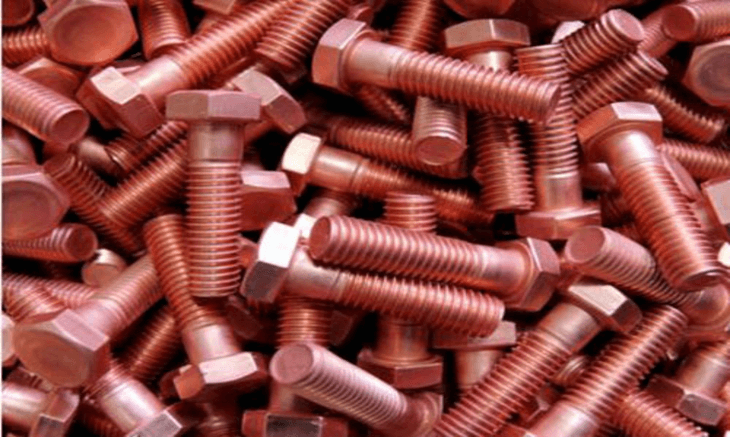

EXPORTERS , STOCKIST & MANUFACTURER OF CUPRO NICKEL BOLTS, CU-NI BOLTS

Nesco Engineering, a distinguished player in the global market, specializes in the manufacture, export, and supply of a diverse range of Cu-Ni Bolts to clients both domestically and internationally. Our product lineup encompasses Cu-Ni Bolts in various sizes, specifications, and tailored dimensions to cater to the unique needs of different industries. These bolts are meticulously crafted under the vigilant oversight of a dedicated and experienced team of professionals who adhere to rigorous national and international quality standards.

COPPER NICKEL BOLTS SUPPLIERS

COPPER NICKEL 70 / 30 BOLTS, COPPER NICKEL FULL THREADED HEX BOLTS, CUPRO NICKEL HEAVY HEX BOLTS EXPORTER, COPPER NICKEL HEX BOLT MANUFACTURER, COPPER NICKEL 90 / 10 BOLTS, CU-NI BOLT STOCKIST, CU-NI BOLTS SUPPLIERS IN MUMBAI INDIA.

Table of Contents

What is Copper Nickel Bolt ?

Copper Nickel Bolt Specification

Ready Stock of Copper Nickel Bolts

Copper Nickel Bolt Price

Widest Stock of Copper Nickel Bolts

Approved In The Following Top Refineries Across The Globe

Application of Copper Nickel Bolts

Nesco Engineering, a distinguished player in the global market, specializes in the manufacture, export, and supply of a diverse range of Cu-Ni Bolts to clients both domestically and internationally. Our product lineup encompasses Cu-Ni Bolts in various sizes, specifications, and tailored dimensions to cater to the unique needs of different industries. These bolts are meticulously crafted under the vigilant oversight of a dedicated and experienced team of professionals who adhere to rigorous national and international quality standards.

At Nesco Engineering, we create Cu-Ni Bolts using a high-quality alloy renowned for its exceptional chemical and mechanical properties. The copper and nickel components within our bolts confer impressive strength and outstanding resistance to corrosion in a variety of environments. Furthermore, our bolts exhibit resilience against issues such as pitting, erosion, and stress corrosion. As a result, Cu-Ni Bolts find widespread applications in diverse industries, including power plants, chemical, paper and pulp, marine, and the petrochemical sector. We pride ourselves on our ability to tailor our products to meet our customers’ specific requirements while upholding the highest standards of quality and reliability.

Nesco Engineering, a leading manufacturer in India, offers a wide range of Cu-Ni bolts, including Cu-Ni J Bolts, Copper Nickel Eye Bolts, Cupro Nickel Square Bolts, Copper Nickel Anchor Bolts, Cu-Ni Flange Bolts, Copper Nickel T Bolts, Copper Nickel Structural Bolts, 70/30 Copper Nickel Carriage Bolts, Copper Nickel U Bolts, and Cu-Ni Lag Bolts.

We are dedicated to staying at the forefront of market trends and continuously improving our strategies to deliver top-notch products and exceptional service satisfaction to our esteemed clients. Nesco Engineering places a strong emphasis on employing advanced manufacturing methods and state-of-the-art equipment to ensure the production of high-quality Cu-Ni Bolts.

To assure the quality and reliability of our products, we provide Test Certificates along with our services. Additionally, we utilize premium packaging materials to safeguard our bolts from any potential damage during transit. Our commitment to customer satisfaction extends to efficient and swift shipping methods, ensuring timely delivery of products to our valued clients.

COPPER NICKEL BOLT SPECIFICATION

| Trade name | Copper Nickel Bolt |

| Copper Nickel Bolt Dimensions | ASTM, DIN, BS, GB, IS and all International Standards |

| Cu-Ni Bolts Size Range | M3 – M56 | 3/6″ to 2″ | Custom Sizes |

| Copper Nickel Bolts Length | 3 mm to 200 mm |

| Copper Nickel Bolts Marking | All Fasteners are marked as follows: Grade, Standard, Thickness, Heat No. (Or according to the customer’s request.) |

| Delivery Time | 7-15 working days as usual, It will based on the detailed order quantity. |

| Payment Terms | Paypal, Western Union, T/T (Telegraphic Transfer or Wire Transfer), L/C or Trade Assurance 30% deposit & balance before shipping |

| Free Sample | Yes if we have in stock |

| Copper Nickel Bolt testing reports |

|

| Cupro Nickel Bolts Origin & Mills | Japanese, Indian, USA, Korean, European, Russian, Ukraine (Strictly No China) |

| Copper Nickel Bolts Application & uses |

|

WIDEST STOCK OF COPPER NICKEL BOLTS

- Large Selection of Cu-Ni J Bolts

- Cu-Ni Countersunk Bolts

- Copper Nickel Elevator Bolt

- Copper Nickel Hanger Bolt Manufacturer

- Copper Nickel Industrial Bolts

- Cupro Nickel Allen Cap Bolt

- Copper Nickel Hex Bolt Supplier

- Copper Nickel Hexagon Head Bolt

- Copper Nickel Shoulder Bolt

- Copper Nickel Lag Bolt

- Copper Nickel Hanger Bolt

- Copper Nickel U-Bolt

- Copper Nickel Eye Bolts

- Copper Nickel T-Head Bolts

- Cu-Ni Anchor Bolts

- Cupro Nickel Machine Bolts

APPLICATION OF COPPER NICKEL BOLTS:

Copper nickel bolts find applications in various industries and situations where their specific properties and corrosion resistance are advantageous. Some common applications of copper nickel bolts include:

Marine and Offshore Industry: Copper nickel bolts are widely used in the marine and offshore industry for fastening components and structures that are exposed to saltwater. Their excellent resistance to corrosion makes them ideal for shipbuilding, offshore platforms, and underwater pipelines.

Power Plants: These bolts are used in power plants, especially in areas where exposure to seawater or brackish water is a concern. They are employed in heat exchangers, condensers, and other components.

Chemical Industry: Copper nickel bolts are suitable for use in chemical processing equipment, where resistance to corrosive chemicals is vital.

Petrochemical Industry: In the petrochemical industry, where exposure to aggressive chemicals and high-temperature environments is common, copper nickel bolts are used in equipment and piping systems.

Desalination Plants: Bolts made from copper nickel alloys are used in desalination plants, where they can withstand the corrosive effects of saltwater.

Paper and Pulp Industry: The corrosion resistance of copper nickel bolts makes them a preferred choice in the paper and pulp industry, particularly in equipment and machinery exposed to chemicals and water.

Heat Exchangers: Copper nickel bolts are used in the construction of heat exchangers for efficient heat transfer and corrosion resistance.

Cooling Systems: They are employed in cooling systems for their corrosion resistance, ensuring long-term performance.

Environmental Protection: Copper nickel bolts are used in environmental protection applications, such as the construction of seawater intake and outfall systems, where they can withstand the harsh conditions.

Desalination Equipment: Copper nickel bolts are used in desalination equipment, where they help maintain the integrity and performance of the systems.

Subsea Equipment: In subsea environments, such as offshore oil and gas installations, copper nickel bolts are used in the construction of various components and structures due to their resistance to seawater corrosion.

Copper nickel alloys, with their combination of copper and nickel, offer an excellent balance of mechanical properties and corrosion resistance, making them suitable for a wide range of industrial and marine applications.